Morn Laser

Exhibition: FABTECH Orlando Date: October 15-17,2024 Location: Orange County Convention Center, Orlando, Florida, USA Booth: S31136

WhatsApp +86 151 6916 6350

-

Product

-

Fiber laser cutting machine

-

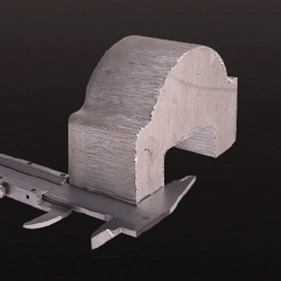

newProfile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality

-

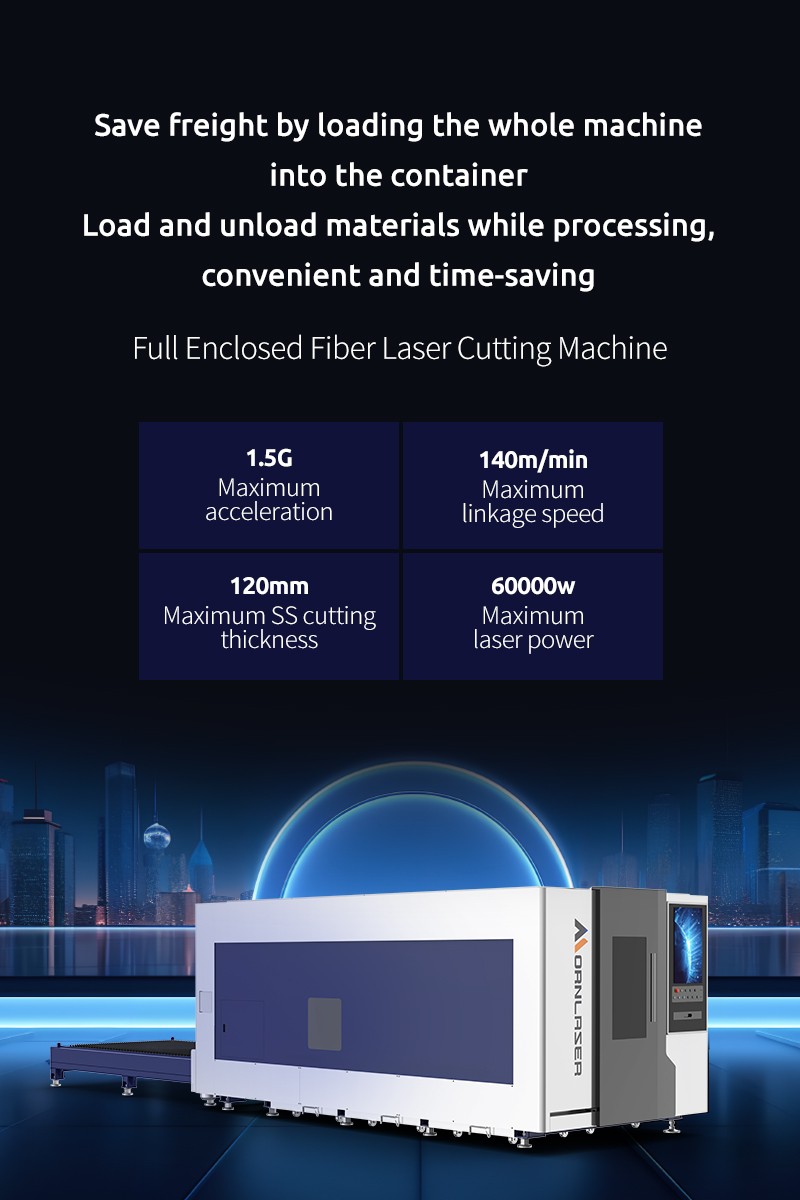

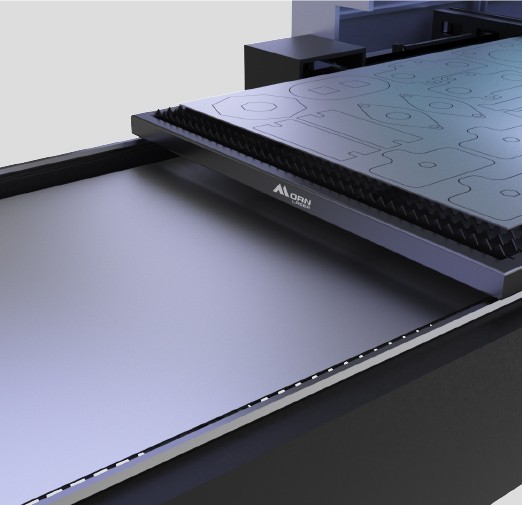

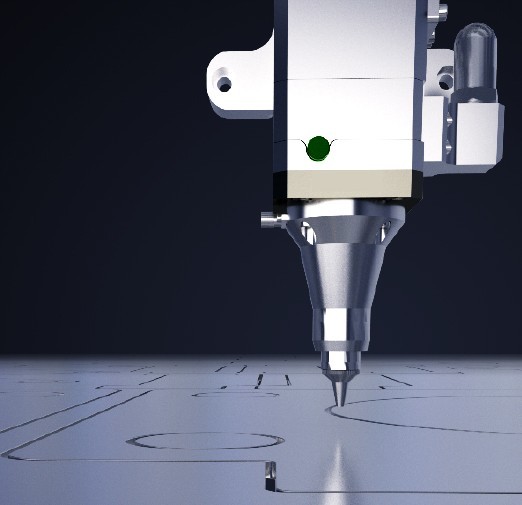

hotFull Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free

-

hotSheet fiber laser cutting machine

tailor-made machine | efficiency boost

-

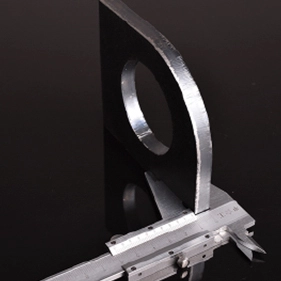

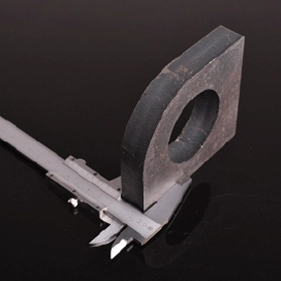

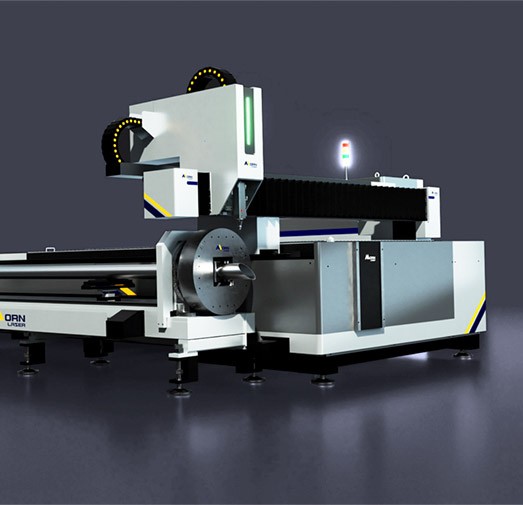

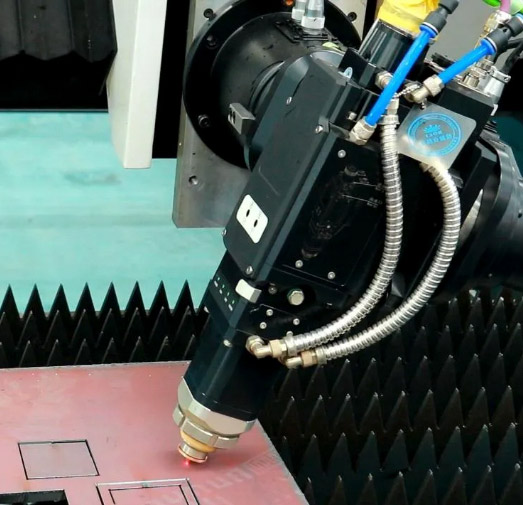

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process

-

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

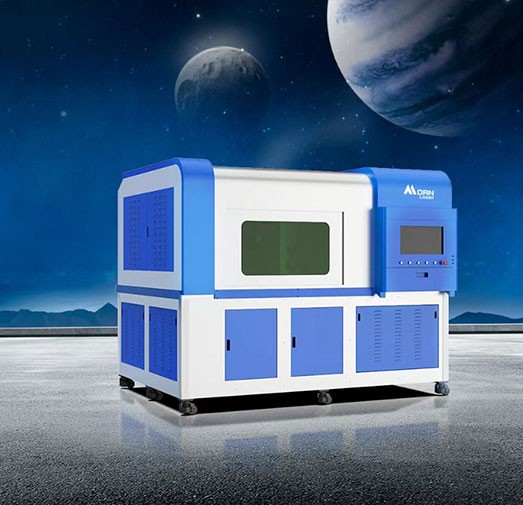

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed

-

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader

-

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing

-

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing

-

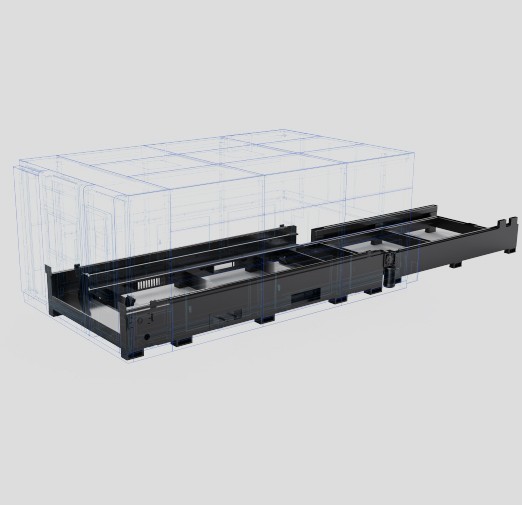

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs.

-

-

Fiber laser welding machine

-

newAir-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective

-

hotAutomatic laser welding machine

fine welding seam | boosted efficiency

-

Integrated fiber laser welding machine

instant welding | easy to operate & move

-

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

-

Fiber laser cutting machine

- Buyer‘s Guide

- Why Morn Laser

- Pricing

- Contact